Aluminium

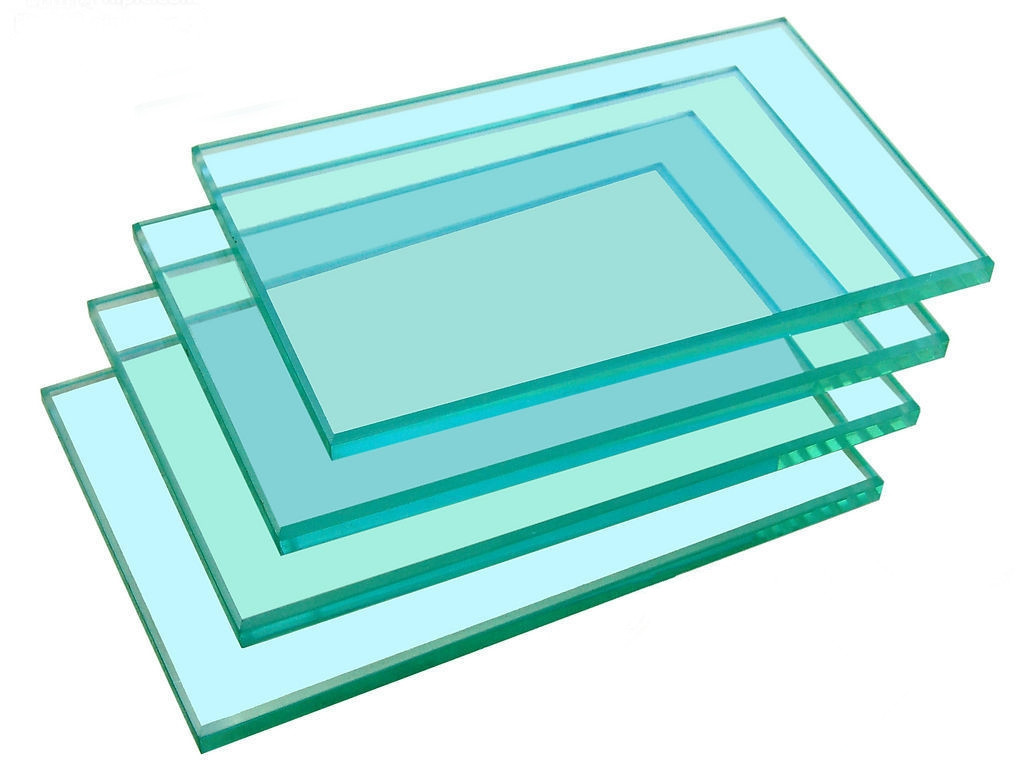

Normal Float Glass

Normal glass is synonymous with flat glass irrespective of the process of manufacture. Float glass has a perfectly flat, brilliant surface, whereas sheet glass has slight distortions. Both are referred as normal (annealed) glass and can be processed to obtain many different varieties of glass for use in buildings. The properties of normal glass are:

• High light transmission

• Optical clarity

• Can be processed to produce other glass types such as tempered, laminated and insulating.

• Colour: Clear, Grey, Bronze, Green, Blue and Pink.

• U value: 5.7 W/sq m K for 12mm thick to 6.4 W/sq. m. K for 19mm thick.

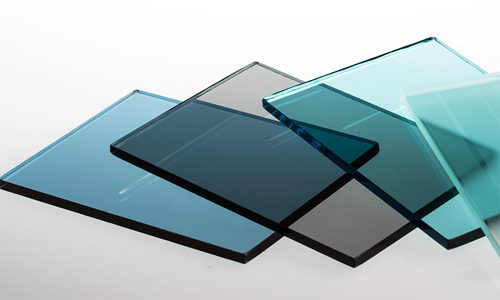

Tinted Glass

It is normal glass that is coloured by the addition of metal oxides into molten glass. Tinted glass possesses filtering properties that help reduce eyestrain due to dazzle. Its absorption properties help diminish energy transmissions when exposed to sunlight. Tints like green allows more visible light and cut out infrared radiation. Applications: Used in doors, windows and partitions etc.

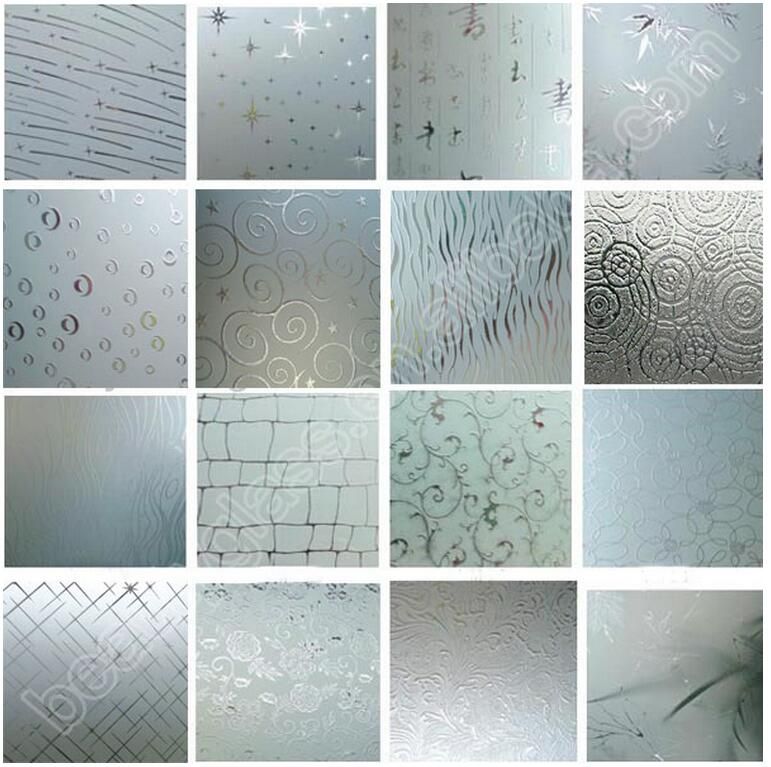

Pattern Glass

It is a decorative and translucent glass with figures or patterns on one face. In addition to diffusing light and obstructing visibility from the outside, the figures soften the interior lighting. This type of glass is usually more fragile and less convenient to clean. Applications: Interiors of the buildings, opaque glazing like bathrooms etc

Reflective Glass

A metallic coating is applied to one side of the glass in order to significantly increase the amount of reflection by the glass of both the visible and infra-red (light and heat) range of the electromagnetic spectrum. This metallic coating can be applied to clear or body tinted glass. The reflective glass imparts a mirror like appearance to the exterior of buildings under most daytime conditions. It reduces heat gain and glare from the exterior and allows optimum visible light transmission to the interior. Applications: Reflective glass is used in office buildings, high-rise buildings,

• Entrance

• Privacy windows

• Decorative walls

• Spandrel glazing

• Vertical and sloped glazing

• Solar control applications

• Building facades

Wired Glass

It has wire mesh incorporated during its production. Wired glass is recommended for its fire protection property. In case of fire, the glass cracks but broken pieces tend to remain in position restricting the spread of flame and smoke for some time. Applications: Used where nominal fire protection is required in windows, doors & partitions etc.

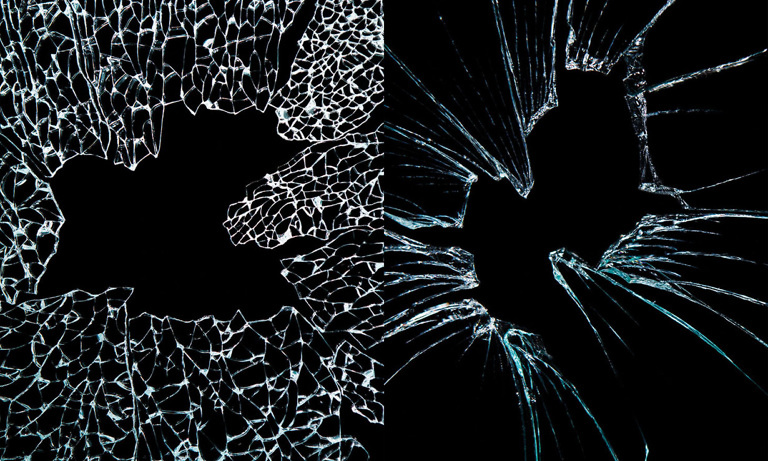

Tempered or Toughened Glass

Tempered glass is an extremely strong glass which is heat treated to a uniform temperature of approximately 650ºC and rapidly cooled to induce compressive stresses of 770 kg/m2 to 1462 kg/m2 on the surfaces and edge compression of the order of 680 kg/m2. Tempered glass is not manufactured on float line. It is a separate process. Tempered or toughened glass gains its added strength from the compressed surfaces. However, if a deep scratch or an impact penetrates the surface, the glass will break into a number of small particles. The heat treatment process for tempered glass requires that all fabrication be completed prior to toughening. Any attempt to cut, drill, grind or sand blast the glass after toughening may result in glass breakage. The heat treatment process does not change the light transmission and solar radiant heat properties of the glass

Applications

It is used in commercial applications where wind, snow or thermal loads exceed the strength capabilities of normal (annealed) glass such as safety glazing for entranceway, railings, partitions or fire knock-out windows. Tempered glass can be used in balustrades, escalator side panels, handrails, shower screens, bathtub enclosures, sliding/swing doors, squash, racquetball wall, showcases, partitions etc.

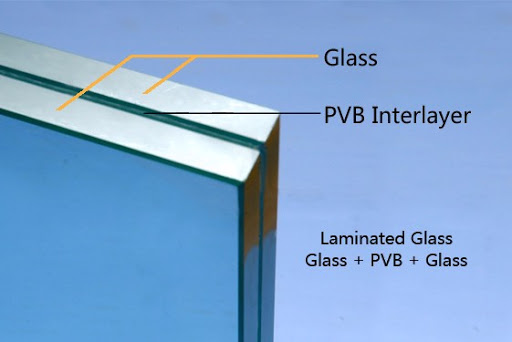

Laminated Glass

Laminated glass is composed of two or more layers of glass with one or more layers of a transparent/ pigmented and specially treated plastic Polyvinyl Butyral [PVB] sandwiched between the glass layers. The glass panes (layers) can be either normal glass or tempered glass. When the glass is broken, fragments tend to adhere to the plastic [PVB] interlayer thereby reducing the risk of injury and helping to resist further damage by weather.

Applications

Laminated glass is used in High security places, for example, banks, teller, and drive-through windows, ticket windows, gas stations, currency exchanges, armoured vehicles, jewellery shops.

Other areas where laminated glass is used are:

• Curtain wall glazing

• Sloped glazing

• Skylights

• Glass roofs & floors

• Aquariums

• Animal observatory windows

• Safety glazing for partitions

• Security glazing for banks against bullets/ hand propelled objects.

Low Emissivity Glass

Low-E, or low-emissivity, glass was created to minimize the amount of infrared and ultraviolet light that comes through your glass, without minimizing the amount of light that enters your home. Low-E glass windows have a microscopically thin coating that is transparent and reflects heat. The coating is even thinner than human hair! The Low-E coatings keep the temperature in your home consistent by reflecting the interior temperatures back inside.

Types of Low-E Coatings

Passive Low-E Coatings (Hard-Coat): The passive Low-E coatings are manufactured using the pyrolytic process, which creates a pyrolytic coating. The coating is then applied to the glass ribbon while it is being produced on the float line, which causes the coating to “fuse” to the hot glass surface. This fusion creates a strong bond, or “hard-coat,” that is very durable.

Solar Control Low-E Coatings (Soft-Coat): Solar control Low-E coatings are manufactured using the Magnetron Sputtering Vapor Deposition (MSVD) process, which means the coating is applied off-line to pre-cut glass in a vacuum chamber at room temperature. This coating, which is also referred to as “soft-coat,” needs to be sealed in an insulated glass (IG) or laminated unit. The soft-coat has lower emissivity and superior solar control performance. This coating offers the highest performing solar control.

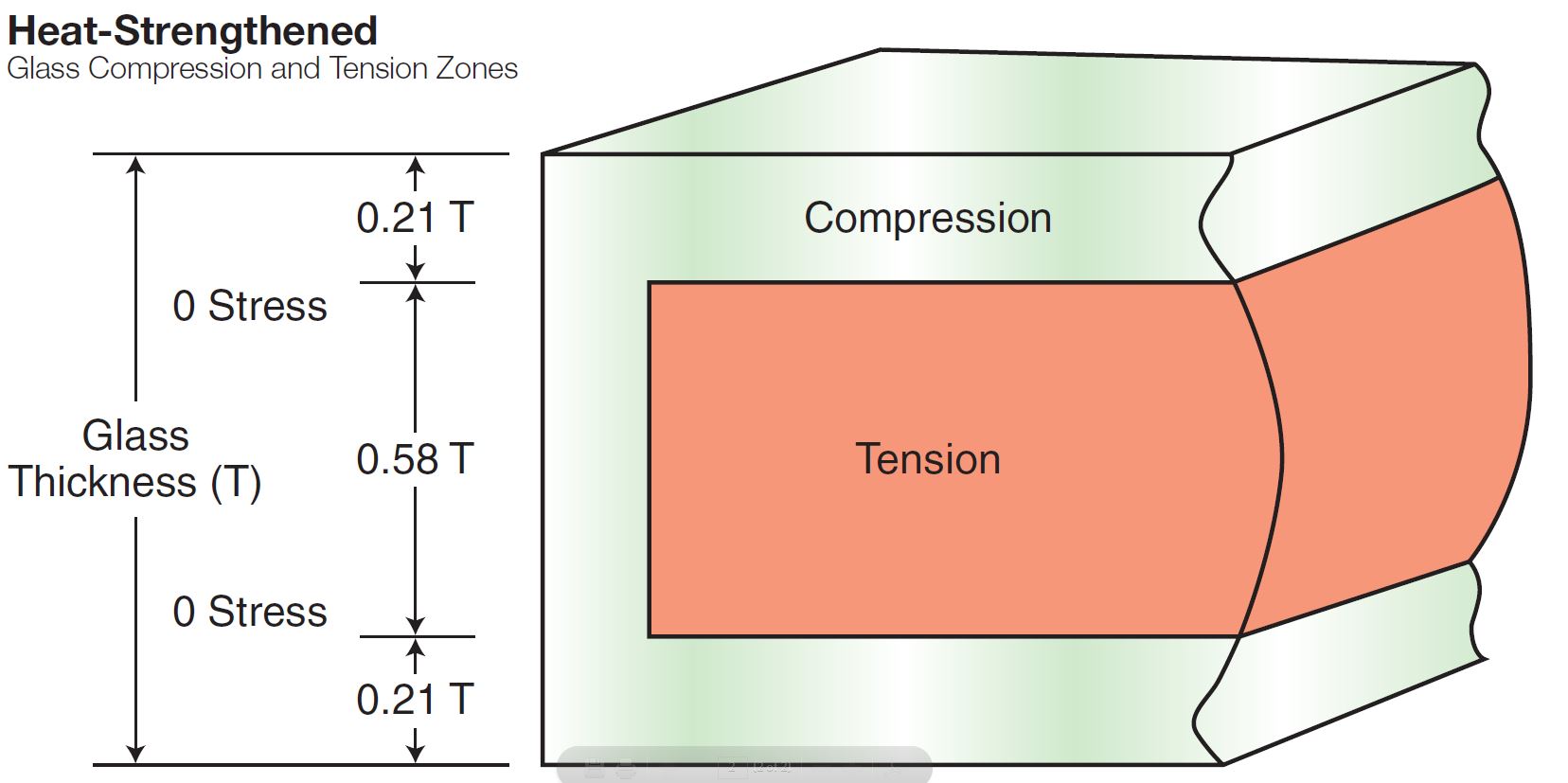

Heat Strengthened Glass

Heat strengthened glass is a type of tempered glass which has been strengthened thermally by inducing a surface compression of 422 to 658 kg/cm2 as compared to a range of 770 to 1462 kg/cm2 in case of fully tempered glass.

Heat strengthened glass is not manufactured on float line. It is a separate process. It is valued for its mechanical strength, which is twice that of normal annealed glass though half of fully tempered glass. With the exception of strength and breakage characteristics, heat - strengthened glass retains the normal properties of annealed glass. Heat-strengthened glass provides necessary resistance to thermal stress associated with high performance glazing materials such as tinted glass and reflective glass. It also provides necessary resistance to heat building up when used as spandrel glass. Heat strengthened glass with its flatter surface also results in the facade having less optical distortions.

Applications

Heat Strengthened glass is suitable for spandrel and vision panels of curtain walls and structural glazing as they safeguard against thermal breakages. It is used for making laminated glass panels for safety combined with strength. It is used in complex glass combinations like double-glazing as one lite of laminated glass for glass floors and roofs.

Low Emissivity Glass

Low-E, or low-emissivity, glass was created to minimize the amount of infrared and ultraviolet light that comes through your glass, without minimizing the amount of light that enters your home. Low-E glass windows have a microscopically thin coating that is transparent and reflects heat. The coating is even thinner than human hair! The Low-E coatings keep the temperature in your home consistent by reflecting the interior temperatures back inside. Types of Low-E Coatings Passive Low-E Coatings (Hard-Coat): The passive Low-E coatings are manufactured using the pyrolytic process, which creates a pyrolytic coating. The coating is then applied to the glass ribbon while it is being produced on the float line, which causes the coating to “fuse” to the hot glass surface. This fusion creates a strong bond, or “hard-coat,” that is very durable. Solar Control Low-E Coatings (Soft-Coat): Solar control Low-E coatings are manufactured using the Magnetron Sputtering Vapor Deposition (MSVD) process, which means the coating is applied off-line to pre-cut glass in a vacuum chamber at room temperature. This coating, which is also referred to as “soft-coat,” needs to be sealed in an insulated glass (IG) or laminated unit. The soft-coat has lower emissivity and superior solar control performance. This coating offers the highest performing solar control.

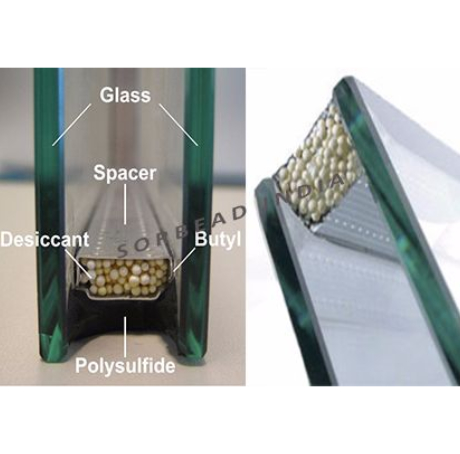

Insulating Glass

The insulating glass is a prefabricated unit made of two or more glass panes, separated by a cavity and edges-hermetically sealed together. This edge seal not only binds the individual sheets of glass together to maintain the mechanical strength of the joint but also protects the cavity between the glasses from outside influences. The moisture in the cavity between the two glasses is controlled by desiccants filled in the perforated spacer. The spacer can be aluminum, composite plastics etc. The spacer ensures the precise distance between the glass panes. The cavity normally filled with dry air but can be also filled with gases such as Argon, Krpton for better thermal performance or hydrogen fluro oxide for better acoustic performance. The low heat conductivity of the enclosed dry gas between the glass panes drastically reduces the thermal heat transmission through the glass 2.8 W/sqmK as compared to 5.73 W/sqm K for normal glass. It also helps is reducing the direct solar energy specifically when the outer pane is a solar control glass.

Applications

• Office buildings, hospitals, hotels, houses and buildings with exceptionally high heating or cooling requirements.

• Buildings that need the temperature and humidity strictly controlled such as telephone exchanges, laboratories, etc.